Preloading vs. ‘Heavy Engineering’ Solutions for Road Embankment Foundation

Jonathan Chun Yu Cheng, Laura Evelyn, Nick Dewar — Arup

The opportunity

Arup was tasked with designing the foundation for a road foundation in the Sydney metropolitan area. The site consisted of soft reclaimed and alluvial sediments at a depth of 12 to 20 meters, which presented a challenge for the foundation design. Arup saw an opportunity to explore alternative design solutions in lieu of ‘heavy engineering’ solutions which had been used in the tender design and similar neighboring sites, ultimately to reduce the embodied carbon and cost of the project.

Objectives

One of the primary objectives of the project was to reduce the embodied carbon of the foundation design relative to the OTD (Original Tender Design) and demonstrate that alternative design solutions can also be practical and cost-effective.

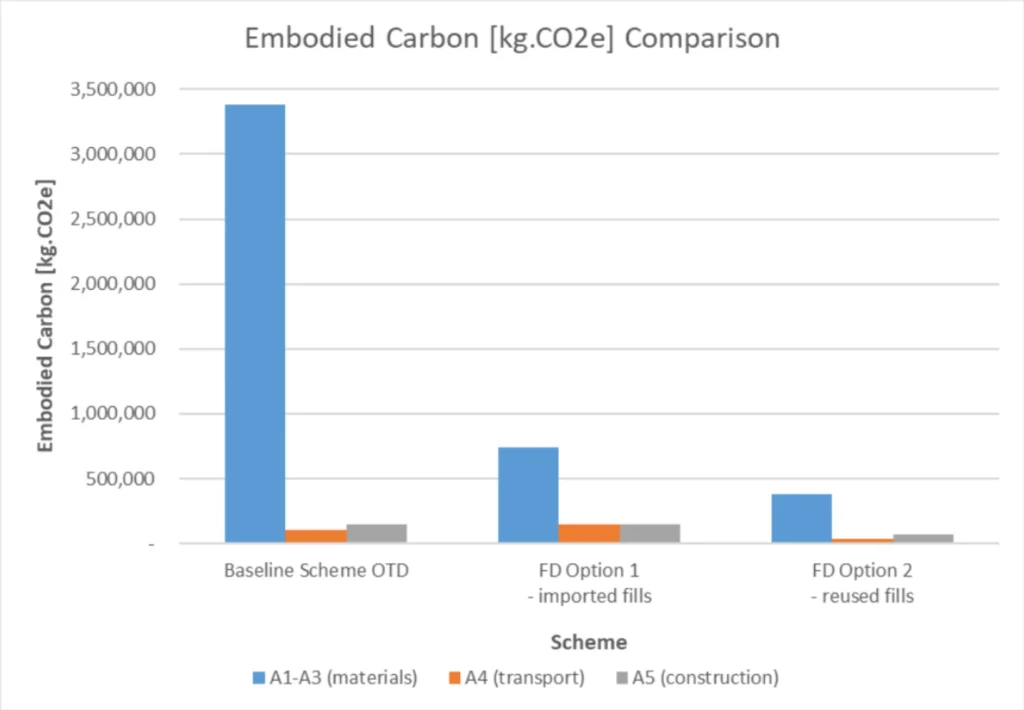

Figure 1: Embodied carbon comparisons between OTD and final design options.

A different approach

Instead of using traditional ‘carbon heavy’ foundation designs such as raft footings or piled foundations, Arup investigated the option of preloading and surcharging. Additional field investigations (BHs, CPTs) and tests (dilatometers and labs) were undertaken to inform the ground model and parameters for detailed numerical analyses. This led to an alternative design solution that utilised fill materials and proper drainage techniques, such as Prefabricated Vertical Drains (PVDs), to replace the OTD of piling and concrete supported slabs.

Two alternative final design solutions were proposed.

- Surcharge and preloading with virgin fill and,

- Surcharge and preloading using reused fill

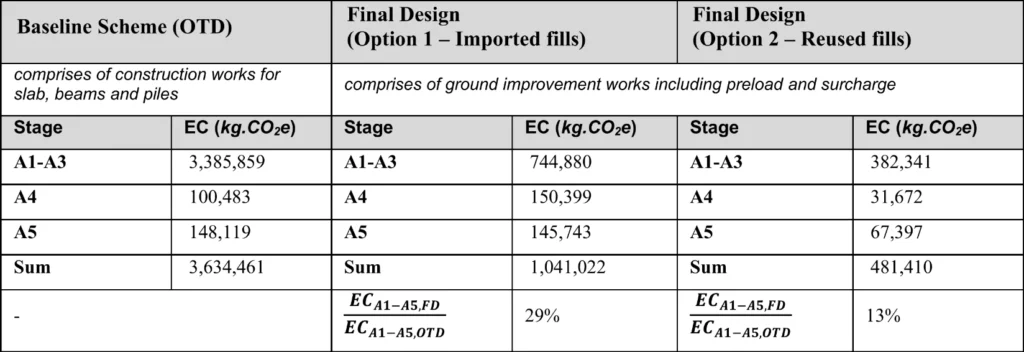

Table 1: Summary of embodied carbon calculations of original tender design and alternative design options.

Key learnings

An embodied carbon assessment was undertaken to understand the carbon savings that occurred from the original tender design to the final design. The assessment showed:

- The final design, using imported fills, was ~ 30% of the embodied carbon for the baseline original tender design (OTD).

- Using site won or reused fills further reduced the embodied carbon by ~50%

Summary

- Reducing new structure volumes (concrete, steel) key to reducing embodied carbon. ‘Less is best’.

- By undertaking additional geotechnical investigation and analysis, design engineers can significantly reduce structure volumes. ‘Smart engineering’

- Reuse fill or material whenever possible.

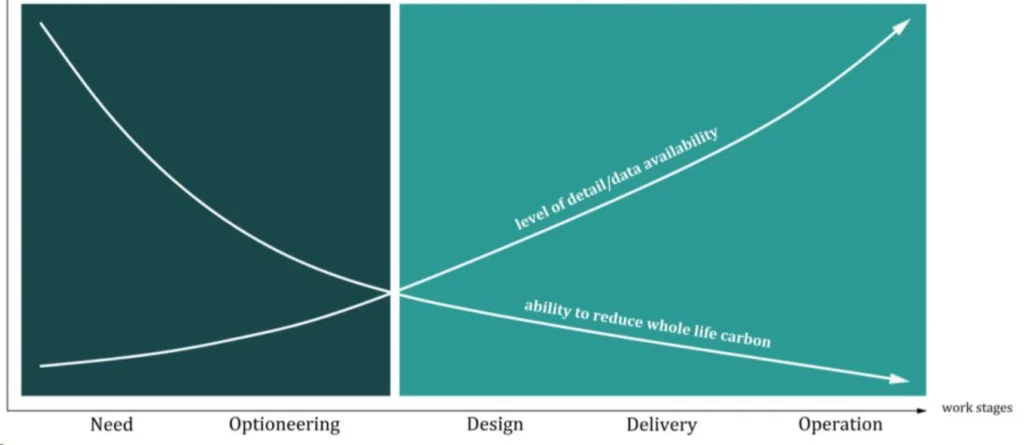

Figure 2: Plot illustrating data availability and the ability to reduce carbon in different work stages (BSI, 2023)